Laser Cut Woodworking Mastery: Expert Techniques for Cutting MDF, Plywood, and Beyond

Woodworking has been revolutionized with the introduction of wood laser cutters, allowing for precision cuts, intricate designs, and efficient work on a variety of wooden materials. Whether you're a professional looking to streamline your production process or a hobbyist eager to explore creative projects, understanding how to laser cut MDF, plywood, and other wood types is key.

This comprehensive guide covers the basics of laser cut woodworking and delves into how you can get started, including the differences between Diode and CO2 lasers, cutting techniques for various wood types, popular project ideas, and essential safety and operation tips.

What is Laser Cut Woodworking?

How to Get Started with Laser Cut Woodworking?

What is Laser Cut Woodworking?

Laser cut woodworking utilizes high-powered laser beams to cut or engrave wood. The laser precisely burns or vaporizes the material, resulting in clean, detailed cuts unmatched by traditional tools.

This method is compatible with a variety of wood types and allows for complex designs, making it a popular choice for decorative items, furniture, signage, and more.

How to Get Started with Laser Cut Woodworking?

Getting started with laser cut woodworking involves understanding the two main types of lasers used: Diode and CO2.

Diode Lasers

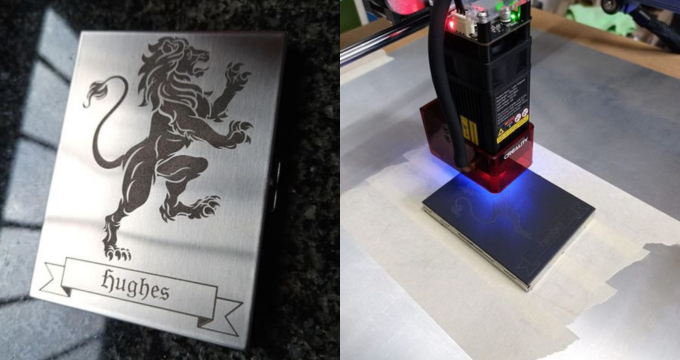

Diode laser cutters are compact, efficient, and utilize semiconductor technology to produce a focused laser beam ideal for etching and marking wood and other thin materials. Typically offering power ranges from 6 to 15 watts, they're better suited for lighter applications and come at an affordable price range of $200 to $1,500. An example of such a machine is the laser engraver from CrealityFalcon, which represents this category of devices.

CO2 Lasers

On the other end, CO2 laser cutters employ a carbon dioxide gas mixture excited by an electric current to generate a powerful laser beam. Invisible to the naked eye, this beam can handle a variety of tasks, including cutting through thicker woods like MDF and plywood with ease. CO2 models vary widely in power, from a few watts to several hundred watts, making them suitable for both hobbyist and professional applications. Their capability to quickly and precisely cut, mark, or engrave wood, alongside their capacity to work with thicker or denser materials, makes them a popular choice despite their larger size and higher cost, which can range from $500 to over $10,000.

The decision between a diode and a CO2 laser cutter largely depends on the specific projects you have in mind. For simple marking or etching, a diode laser is a cost-effective and space-saving option. However, if your ambitions include working with a wider range of materials and tackling more complex cutting tasks, investing in a CO2 laser cutter would be more appropriate.

How to Cut Wood?

Different wood types may require specific considerations for cutting to achieve the best results.

Soft Woods

Soft woods, such as cedar, pine, and balsa, are less dense and can be cut with lower power settings. When cutting soft woods:

- Use Low Power: Start with a lower power setting to prevent burning or excessive charring.

- Test First: Perform test cuts on scraps to find the optimal speed and power settings.

- Watch for Flares: Soft woods can ignite more easily. Keep a close eye during the cutting process to manage any sudden flares.

Hard Woods

Hard woods, including oak, maple, and walnut, are denser and require a more thoughtful approach:

- Increase Power and Decrease Speed: Use higher power settings and adjust the cutting speed to be slower to ensure clean cuts without scorching.

- Multiple Passes: For thicker pieces, several passes at a consistent depth may yield better results than trying to cut through in one go.

- Grain Consideration: Pay attention to the wood grain, which can affect cutting consistency. Cutting perpendicular to the grain might need adjustments in speed.

Plywood

Plywood's layered structure presents unique challenges:

- Varying Density: The alternating layers of wood and glue can affect the laser's ability to cut evenly. Adjust power and speed accordingly.

- Watch for Voids: Plywood may have internal voids that affect the consistency of the cut. Plan for possible imperfections.

- Air Assist: Using an air assist can help reduce flame risks and clear the cutting path from the residue.

MDF

MDF's uniform composition from wood fibers and glue makes it predictable but requires certain considerations:

- Consistent Power: The consistency of MDF allows for uniform power settings across the board.

- Residue Management: MDF can produce more residue when cut, so maintaining clean optics and using air assist can help maintain cut quality.

- Ventilation: Cutting MDF releases more fumes due to its glue content. Ensure good ventilation to maintain a safe working environment.

Popular Laser Cut Wood Projects and Ideas

Here are six popular and inspiring laser-cut wood projects and ideas that can appeal to both beginners and experienced makers:

1. Custom Wooden Jewelry

Here are six popular and inspiring laser-cut wood projects and ideas that can appeal to both beginners and experienced makers:

2. Decorative Wall Art and Panels

Create stunning pieces of wall art, ranging from geometric patterns to detailed landscapes or portraits. Laser-cut wood panels can also serve as unique, eye-catching room dividers or decorative screens, adding texture and interest to any living space.

3. Personalized Coasters and Cutting Boards

Custom coasters and cutting boards are functional yet personal gifts or products. They can be laser engraved with names, dates, logos, or any design that resonates with the recipient, making them a hit at weddings, housewarmings, or as promotional items.

4. Intricate Lamps and Candle Holders

Laser-cut wood can be assembled into beautiful lamps or candle holders. The cutouts allow light to escape in mesmerizing patterns, creating ambient lighting for indoor or outdoor spaces. Designs can range from simple cylinders to elaborate spherical shapes.

5. Puzzles and Educational Toys

Wooden puzzles, from simple shapes for toddlers to complex 3D models for adults, can be crafted with precise cuts, offering a range of educational and entertaining options. Educational toys like alphabet tiles or animal figures can also be laser cut, providing durable learning tools for children.

6. Custom Signage and Home Decor

Laser-cut wooden signs can add a personal touch to any home or business, offering endless possibilities for customization. Welcome signs, house numbers, or inspirational quotes are popular choices. Similarly, holiday decorations can be easily produced, allowing for unique and personal touches to seasonal decor.

Bonus: What to do if you don't have a Laser Cutter?

There are several avenues you can explore to bring your designs to life. Here's what you can do:

1. Visit Makerspaces

Makerspaces are collaborative workspaces equipped with tools and machinery, including laser cutters, accessible for community use. These spaces not only provide the equipment but also offer the opportunity to connect with a community of like-minded individuals. You can learn from others, share your expertise, and collaborate on projects.

2. Use Online Cutting Services

Numerous online platforms offer laser cutting services. Simply upload your design, choose your material, and specify your dimensions. These services can precisely cut or engrave your designs on a variety of materials, and the finished product will be shipped directly to you. This option removes the need for personal equipment and is perfect for occasional projects or experimenting with laser cutting.

3. Consider Purchasing a Laser Cutter

For those who are serious about incorporating laser cutting into their craft, buying a laser cutter might be a worthwhile investment. Take, for instance, the Creality Falcon2 Pro Laser Engraver. This machine stands out with its substantial and secure design, offering innovations for all levels of passion in crafting and business ventures alike.

The Creality Falcon2 Pro is recognized for its safety, sporting an FDA Class 1 Safety Certification. Its deep red, highly transparent cover is designed for eye-friendly viewing, minimizing stress while watching your projects come to life. Equipped with dual sensors for sealing status and lid-off halts, it provides a worry-free creative environment.

Its 360° visual design is a blend of aesthetics and functionality, allowing you to monitor the progress from any angle without needing protective glasses. The machine's high efficiency, supported by the option of 40W or 22W laser modules, grants super cutting power, capable of handling small to batch projects effortlessly. The spacious 15.75*16.34 inches working area breaks free from spatial constraints, enabling a wide range of possibilities.

People also read:

How to Create a Personalized Laser Engraved Tumbler >>

Creality Falcon 2 Pro Review >>

Final Words

The world of wood laser cutting offers endless possibilities for both beginners and seasoned professionals. With the right tools, a bit of practice, and a dash of creativity, you can bring intricate designs to life, add personal touches to your projects, or even start a new business based on laser-cut wood products. Remember, safety comes first, so always follow your laser cutter's operating and safety guides.

Embark on an exciting journey into the realm of laser cut woodworking with the CrealitFalcon Laser Engraver, a perfect companion for artisans at every skill level.

Greetings, greetings all. Love my 10w falcon. This thing exceeded my expectations like crazy. Works like a charm and so easy to build.

Greetings, greetings all. Love my 10w falcon. This thing exceeded my expectations like crazy. Works like a charm and so easy to build.