Basswood vs. Plywood: A Comprehensive Guide on Their Differences and Interaction with Diode Lasers

When it comes to woodworking, the choice of material can significantly influence the outcome of your project. Two of the most common materials used in various woodworking ventures are basswood and plywood. Both have unique characteristics that make them suitable for specific applications. This article aims to provide a detailed comparison between basswood and plywood, and we'll also delve into how they interact with diode lasers, which are often used in cutting and engraving processes.

Basswood vs. Plywood: Understanding the Basics

Basswood, also known as Tilia or Lime in the UK, is a type of hardwood. It is harvested from the Tilia tree, which is native to North America and Europe. Basswood is favored by many craftsmen for its light color, fine grain, and soft texture. It is easy to work with, enabling smooth cutting and carving. Basswood is often used in making musical instruments, model kits, carving blocks, and even in the manufacturing of some furniture.

Plywood, on the other hand, is not a type of wood, but a composite material. It is made by gluing together multiple thin layers, or 'plies,' of wood veneer. The layers are oriented with their grain directions at right angles to enhance the panel's strength. Plywood's strength, affordability, and ease of accessibility make it a popular choice for numerous applications including construction, furniture-making, and crafting.

Interacting with Diode Lasers: Basswood and Plywood

Diode lasers are commonly used in woodworking for cutting and engraving due to their precision and efficiency. The way these two types of wood interact with diode lasers can vary significantly.

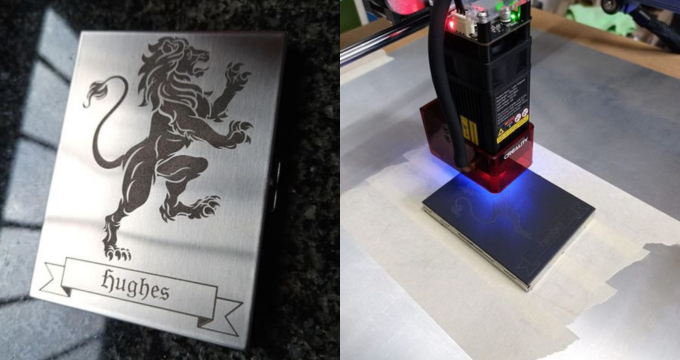

Basswood, with its soft and uniform texture, is ideal for laser cutting and engraving. Its light color also provides a nice contrast when engraved, making the details stand out. However, due to its softness, basswood may require lower power settings and slower cut speeds to avoid burning or charring.

Plywood can also be cut and engraved with a diode laser, but the results can be inconsistent due to its layered structure. Depending on the type of wood used in the veneers and the quality of the glue, laser cutting or engraving plywood can sometimes result in irregular edges or uneven engraving depths. Higher quality plywood tends to yield better results with diode lasers.

Safety should be paramount when using diode lasers with any type of wood. Always use appropriate protective equipment, ensure proper ventilation, and never leave the laser unattended during operation.

In Conclusion

Basswood and plywood, while both popular in woodworking, have distinct differences. Basswood, a soft hardwood, is favored for its fine grain and ease of carving, while plywood's strength and affordability make it a go-to for construction and furniture making. When it comes to working with diode lasers, basswood tends to provide more consistent results due to its uniform texture, while plywood's performance can vary based on its composition. Understanding these differences can help you select the most appropriate material for your next woodworking project.

-

Basswood vs. Plywood: Understanding the Basics

-

Interacting with Diode Lasers: Basswood and Plywood

-

In Conclusion

Greetings, greetings all. Love my 10w falcon. This thing exceeded my expectations like crazy. Works like a charm and so easy to build.

Greetings, greetings all. Love my 10w falcon. This thing exceeded my expectations like crazy. Works like a charm and so easy to build.