Edited by: Henry Lin, Creality Rachel

Technical Support and Consultant: Filix Li, Henry Lin, Nordine Zouaoui

How often do you do maintenance for your laser engraver? I find some of our users experience machine stops or malfunctions due to contaminated lens, loose belt and so on. A regular maintenance routine can help your laser keep a good performance and extend lifespan. This guide will walk you through the essential steps and best practices for maintaining your laser machine, helping you to keep it in top condition.

Routine Inspection

The frequency of cleaning and inspecting your laser engraver should align with how often you use it. For instance, if you operate your laser 3-4 times a week, it’s advisable to follow this maintenance routine weekly. To ensure your laser engraver remains in optimal condition, carry out the following checks:- Cable Inspection: Regularly examine all cables for any signs of looseness or damage.

- Laser Head and Lens Check: Ensure the laser head and lens are clean and clear of any debris.

- Optical Component Examination: Look for any dirt, contamination, or scratches on the optical components.

- Belt Inspection: Check the belt for proper tension and signs of wear.

- Overall Cleanliness: Conduct a general assessment of the machine’s cleanliness, covering all areas.

Lens Cleaning

For Falcon2 laser users, there's a LENS indicator on the laser module. When the light flashes orange or red, it’s time to make a lens cleaning. You can also turn off the laser and remove the laser head to check if the lens was contaminated.

- Reference video:

Lens Replacement

If you find that cleaning the lens is impossible due to heavy contamination or if you notice broken cracks on the lens, it’s time to replace it with a new protective lens. Follow these steps for lens replacement:

- Reference video:

Laser Module Cleaning

Yes, you can actually clean the laser module as well. Although our laser modules are well protected by external casings, they can still become dirty over time, especially with significant amounts of dust and wood shavings after crafting works. We recommend that you regularly clean your laser module, depending on the frequency of your laser work. Refer to the video below and use the dust-free cloth and anti-static brush that come with the product for a thorough cleaning of your laser module.

- Reference video:

Belt Maintenance

- Checking belt tension and adjusting if necessary:

- Turn off the laser cutter and disconnect power.

- Locate the belts on the motion system.

- Gently press on the belt midway between pulleys; it should deflect slightly.

- Adjust tension if necessary according to the manufacturer’s guidelines.

- Lubrication guidelines for the belt and associated components:

- Follow the manufacturer’s recommendations for the type and application of lubricant.

- Apply lubricant sparingly to the belt and associated components.

- For CR Falcon or machines with rods or rails, a thin layer of grease can be added after cleaning to rejuvenate its lubricity.

- Wipe off any excess lubricant to prevent accumulation of debris.

- Inspecting the belt for signs of wear or damage:

- Perform a visual inspection of the entire length of the belt.

- Look for signs of fraying, cracks, or other visible damage.

- If any damage is found, replace the belt promptly.pin

- Reference video:

Air Assist

The air pump is also a module you need to do regular check. Whenever you feel the air flow weaken, time to give the air pump a proper check and clean.

- Inspecting air pump cable for any signs of air leaks or damage

- Replace or clean the filter of air assist.

- Reference Video:

User Tips for Prolonging Equipment Life

Best practices for optimal laser cutter usage according to optimal cutting parameters:

- Set cutting parameters according to the material being processed.

- Not all materials need to be cut at 100% power; adjust settings based on material requirements.

- Adhere to recommended guidelines for power, speed, and focus settings.

- Regularly check and calibrate the laser power to ensure accurate and efficient cutting.

- Monitor and adjust cutting parameters for different material thicknesses.

- Implementing optimal cutting practices contributes to extended equipment life and consistent cutting quality.

Appendix

Creality Wiki: Visit the Creality Wiki for additional resources and documentation.

For additional tutorials, please check the CR Falcon YouTube page for video guides.

-

Routine Inspection

-

Lens Cleaning

-

Lens Replacement

-

Laser Module Cleaning

-

Belt Maintenance

-

Air Assist

-

User Tips for Prolonging Equipment Life

-

Appendix

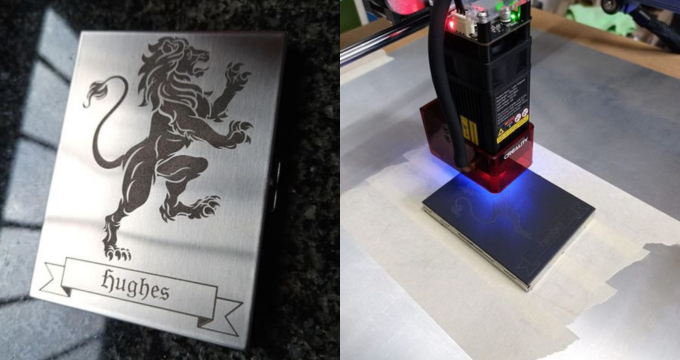

Greetings, greetings all. Love my 10w falcon. This thing exceeded my expectations like crazy. Works like a charm and so easy to build.

Greetings, greetings all. Love my 10w falcon. This thing exceeded my expectations like crazy. Works like a charm and so easy to build.