Glass etching, a timeless art, lets creators shape glass into intricate designs. Modern tech brings laser etching to the forefront, enabling precision and consistency. Whether you're new to glass etching or a seasoned pro, our guide is your gateway.

Dive deep into laser etching, discover its benefits, and grasp step-by-step instructions. Unleash your creativity with inspiring ideas and find your perfect etching machine. Let's embark on your glass etching journey!

Part 1: How Does Engraving Work?

Part 2. What is Laser Glass Etching?

Part 3. Advantages of Laser Etching and Engraving Glass

Part 4. How to Laser Etch/Engrave Glass: A Step-by-Step Guide

Part 1:How Does Engraving Work?

In essence, the high-temperature laser beam vaporizes material and carves cavities, and glass's unique composition makes this possible. Glass is crafted by heating silicon to create a thick, fluid substance.

As it cools, air and moisture become trapped in its structure. When a laser beam interacts with the glass, it's the air and moisture that react, not the silicon. This reaction causes microscopic fractures on the rigid glass surface, creating the engraving's distinctive texture and appearance.

1: Engraving Curved Glass

Laser engraving is a straightforward process on flat surfaces with consistent distances and focal lengths. However, when dealing with curved objects like bottles or vases, challenges arise.

To address this, a rotary attachment comes into play. This accessory, integrated with the laser machine, enables the glass object to rotate, allowing the laser to work its magic. Nonetheless, intricate curves and angles can still present difficulties in achieving precise engraving results.

2: Neatness & Cleaning

Glass engraving may involve fracturing and chipping, but the aim is to create a shard-free design. To achieve this, engravers often place wet paper towels or newspapers over the glass during the process.

Post-engraving, cleaning is essential. Rubbing alcohol and a paper towel or a nail brush can be used, especially if there are shards. Alternatively, application tape is another option to maintain a smooth surface and prevent roughness.

Part 2:What is Laser Glass Etching?

Glass etching is an art that entails crafting intricate designs or images on glass by delicately removing a small amount of material from its surface. Over time, a spectrum of techniques has emerged, encompassing both traditional and contemporary methods to achieve this beautiful effect.

Traditional glass etching methods encompass:

- Acid Etching:Utilizes hydrofluoric acid to dissolve glass surfaces, yielding a frosted appearance. Caution is crucial due to its corrosive nature.

- Sandblasting:Involves high-pressure air propelling abrasives, such as sand or silicon carbide, to create a textured, frosted effect. While offering control, it demands specialized equipment.

- Glass Etching Cream:A safer alternative, it employs chemicals reacting with the glass to create a frosted look, easily applied by DIY enthusiasts using a brush or stencil.

Modern techniques, including laser etching and engraving, have emerged with advanced technology. These methods use a focused light beam to precisely remove glass material, resulting in intricate designs.

While the terms "etching" and "engraving" are often used interchangeably, the distinction lies in the depth of the mark—etching is shallower, while engraving is deeper. Laser methods are praised for their precision, consistency, and efficiency.

Part 3:Advantages of Laser Etching and Engraving Glass

Laser etching and engraving have become a preferred choice for glass artisans, professionals, and enthusiasts due to a multitude of advantages over traditional etching methods. Here's why lasers have gained such popularity in glass etching:

- Precision and Detail: Laser engravers boast unmatched precision. A computer-guided system, often referred to as CNC (Computer Numerical Control), ensures the laser's exact movement. The result? Intricate and highly detailed designs, patterns, and text on glass surfaces. With laser settings adjustments for power and speed, users enjoy precise control over the etching process.

- Consistency in Reproduction: Computer control enables easy replication of designs with utmost precision. This consistency is invaluable for producing multiple identical pieces or large-scale projects.

- Speed and Efficiency: Laser etching is notably faster than traditional methods. Guided by CNC, the laser moves swiftly across the glass surface. This real-time coordination translates digital designs into rapid laser movements, minimizing production times and increasing output.

- Minimal Material Waste: Laser etching removes a minimal amount of material, ensuring minimal waste. This environmentally conscious approach stands in stark contrast to sandblasting, which generates considerable dust and debris.

- Environmentally Friendly: Unlike acid etching and glass etching creams, laser etching is chemical-free. This eco-friendly process eliminates concerns about chemical disposal and environmental harm.

Opting for laser glass etching provides a harmonious blend of precision, consistency, speed, and environmental friendliness. It has revolutionized the world of glass artistry, making it a top choice for those who seek the finest in etching techniques.

Part 4:How to Laser Etch/Engrave Glass: A Step-by-Step Guide

Glass etching with CO2 lasers is a precise art. Here are key steps:

- 1Choose the right glass type.

- 2 Ensure a spotless glass surface.

- 3 Design your artwork in compatible software.

- 4 Set the laser power and speed.

- 5 Prioritize safety with goggles and ventilation.

- 6 Position, focus, and initiate the etching.

- 7 Afterward, clean the glass and review the results.

This method's finesse allows you to create intricate designs on various glass types, from flat sheets to curved surfaces like wine glasses, with ease and precision.

Bonus:Revolutionize Your Glass Etching Projects with the Creality Falcon2 40W Laser Engraver & Cutter

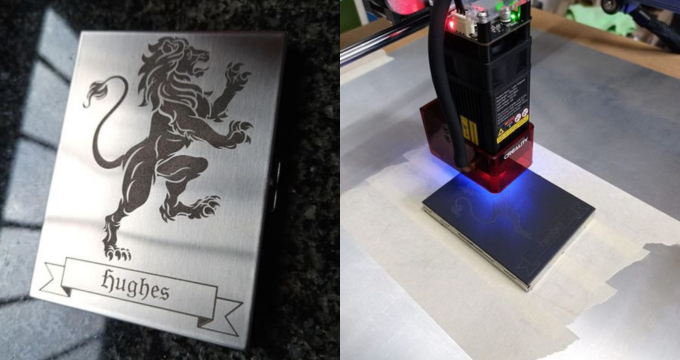

Are you ready to take your glass etching projects to the next level? The Creality Falcon2 40W Laser Engraver & Cutter is your key to unlocking a world of limitless creative possibilities. With its powerful 40W laser output and lightning-fast cutting speed of 25000mm/min, you can achieve intricate, ultra-fine carvings on glass, ceramics, and even stainless steel with ease.

But that's not all. This versatile machine comes with five advanced safety features to ensure your peace of mind, making it ideal for both professionals and hobbyists. Whether you're working on personalized gifts, home decor, or intricate art pieces, the Falcon2 is your trusted companion.

Don't miss out on the chance to elevate your glass etching game. Discover the magic of the Creality Falcon2 and let your creativity shine!

Final Thoughts!

Explore the precision and efficiency of laser etching glass with Creality Falcon2 40W Laser Engraver & Cutter. Create intricate designs and personalize glass items with laser-etched glass. This tool allows for quick processing and minimal surface damage, unlocking limitless possibilities. Prioritize safety while exploring your creative ideas. Elevate your art and craftsmanship with Creality Falcon2.

-

Part 1:How Does Engraving Work?

-

Part 2:What is Laser Glass Etching?

-

Part 3:Advantages of Laser Etching and Engraving Glass

-

Part 4:How to Laser Etch/Engrave Glass: A Step-by-Step Guide

-

Bonus:Revolutionize Your Glass Etching Projects with the Creality Falcon2 40W Laser Engraver & Cutter

-

Final Thoughts!

Greetings, greetings all. Love my 10w falcon. This thing exceeded my expectations like crazy. Works like a charm and so easy to build.

Greetings, greetings all. Love my 10w falcon. This thing exceeded my expectations like crazy. Works like a charm and so easy to build.