Enhancing Safety and Efficiency with Laser Engraver Enclosures

Dealing with Laser Engraver Smoke

One of the primary challenges in laser engraving is managing the smoke and fumes generated during the process. This smoke, often a mix of particulate matter and potentially toxic gases, is a byproduct of the material being vaporized by the laser. Effective management of this smoke is crucial, not just for the health and safety of the operator but also for maintaining the quality of the engraving. Ventilation systems and air filtration are key components of laser engraver enclosures, designed to efficiently remove smoke from the engraving area and filter out harmful particles and gases. This not only ensures a safer working environment but also prolongs the life of the laser engraver by keeping its components clean.

The Necessity of an Enclosure for Laser Engravers

The question of whether an enclosure is necessary for a laser engraver is often answered by considering the safety and operational efficiency it offers. An enclosure serves multiple purposes: it contains the smoke and debris, reduces noise, and most importantly, provides a safety barrier between the laser and the operator.

The Primary Purpose and Benefits of Using an Enclosure with a Laser Engraver

Laser engraver enclosures are designed to enhance the safety and efficiency of the engraving process. They protect the operator from direct exposure to laser beams, which can cause serious eye damage and skin burns. Enclosures also prevent accidental contact with moving parts of the machine. Furthermore, they contain the noise produced during engraving, making the process more comfortable in a shared workspace.

Importance of Safety in Laser Engraving

Hazards Associated with Laser Engraving

Laser engraving poses several hazards, including exposure to intense laser beams, fumes, and fire risks. The intense beam can cause severe eye injuries and skin burns if not properly contained. The process also generates fumes and particulate matter, which can be hazardous when inhaled, especially over prolonged periods.

Role of Enclosures in Enhancing Safety

Enclosures play a critical role in mitigating these risks. They are designed to shield the operator from direct laser exposure and contain any fumes and particulate matter. Enclosures often come equipped with safety interlocks, which prevent the laser from operating when the enclosure is open. This is a critical feature that ensures the laser can only be operated under safe conditions.

Types of Laser Engraver Enclosures

Designs and Materials

Laser engraver enclosures come in various designs: fully enclosed, partial enclosure, and custom designs. Common materials used include polycarbonate, acrylic, and metal. Each material has its pros and cons, with factors like durability, cost, and effectiveness at containing fumes and noise playing a role in the selection.

Pros and Cons

Fully enclosed designs offer the best protection and fume management, while partial enclosures might be more accessible but offer less containment. Metal enclosures are durable and effective

in fire prevention, whereas acrylic and polycarbonate provide visibility but may not be as robust.

Key Features of Laser Engraver Enclosures

Ventilation Systems and Air Filtration

These are essential for removing harmful fumes and smoke. Quality enclosures have efficient ventilation systems that ensure clean air circulation, protecting both the user and the machine.

Safety Interlocks and Emergency Stops

Safety interlocks ensure that the laser cannot operate when the enclosure is open, preventing accidental exposure to the laser beam. Emergency stops provide an additional layer of safety, allowing for immediate shutdown of the machine in case of an emergency.

Visibility and Access

Good enclosures offer clear visibility to the working area, allowing for monitoring of the engraving process. They also provide easy access for maintenance and adjustments.

Noise Reduction

Enclosures can significantly reduce the noise generated by the engraving process, making for a more comfortable working environment, especially in shared spaces.

In summary, the incorporation of a laser engraver enclosure is not just a safety measure but a significant enhancement to the overall engraving process. Enclosures like the Crealityfalcon Laser Engraver Enclosure Pro underscore this point effectively. Designed with an enclosed structure, this model excels in isolating smoke and dust, a crucial factor in maintaining a clean and safe workspace. The built-in exhaust system not only removes smoke and dust but also purifies the air, ensuring a healthier environment for operators and reducing the contamination of engraving materials.

-

Dealing with Laser Engraver Smoke

-

The Necessity of an Enclosure for Laser Engravers

-

Importance of Safety in Laser Engraving

-

Types of Laser Engraver Enclosures

-

Key Features of Laser Engraver Enclosures

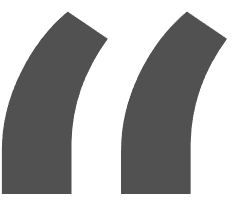

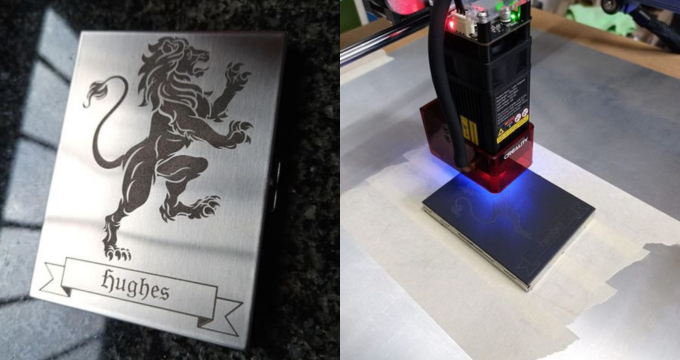

Greetings, greetings all. Love my 10w falcon. This thing exceeded my expectations like crazy. Works like a charm and so easy to build.

Greetings, greetings all. Love my 10w falcon. This thing exceeded my expectations like crazy. Works like a charm and so easy to build.

Leave a comment

All blog comments are checked prior to publishing